TECHNOLOGIES

An Audio Component Rack – it’s not just furniture, it’s a sophisticated, multitasking structure designed to meet specific requirements.

Location of the equipment

Our audio racks are built to withstand significant weight. The MDF shelf thickness (a material known for its resilience to resonance) in our standard configuration is 27 mm, far exceeding what is strictly necessary. However, at the client’s request, shelf thickness can be increased to 40 mm. Additionally, clients can customize the distance between shelves to accommodate their specific equipment requirements.

Vibration Damping Materials

A rigid structure is ensured by the vibration-absorbing filling of the profile. Multiple isolation levels guarantee optimal sound quality. The rack is isolated not only from the floor but also individual shelves are isolated. This task is accomplished by dampers and spikes, manufactured using our proprietary technology and extensively field-tested.

Ideal surface.

In our manufacturing process, we use the most technologically advanced equipment from leading global manufacturers. This enables us to achieve the highest standards of production quality.

In our models, we exclusively utilize top-quality polished glass (grade M0) from the leading global manufacturer, AGC.

Customization

Moreover, we happily collaborate on bespoke projects tailored to our clients’ needs.

Sometimes, unexpectedly, we create not only unique but also masterful acoustic racks.

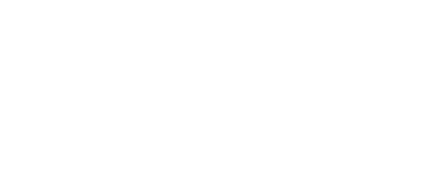

Acoustic decouplers

As part of our overall design and manufacturing concept, specialized supports have been developed to install and position Hi-Fi & High-End components. These supports are aimed at reducing external and interconnect vibrations and interference.

The primary objective in developing these supports was to enhance resolution and tonal balance by reducing the contact area between surfaces, thus minimizing detrimental mechanical energy generated within electronic components. This approach also mitigates mutual influence between individual elements of the system, leading to decreased mutual vibrations.

The supports are designed as a sandwich structure, both elastic and rigid simultaneously. To describe it simply: between two metal discs made from various materials lies a special sphere, which minimizes the contact area between the support discs. The entire structure is enclosed in a casing made from a special inert material, ensuring the integrity of the construction and preventing slipping.

These products are recommended for use alongside component platforms as supports and have proven to work excellently with vinyl record players.

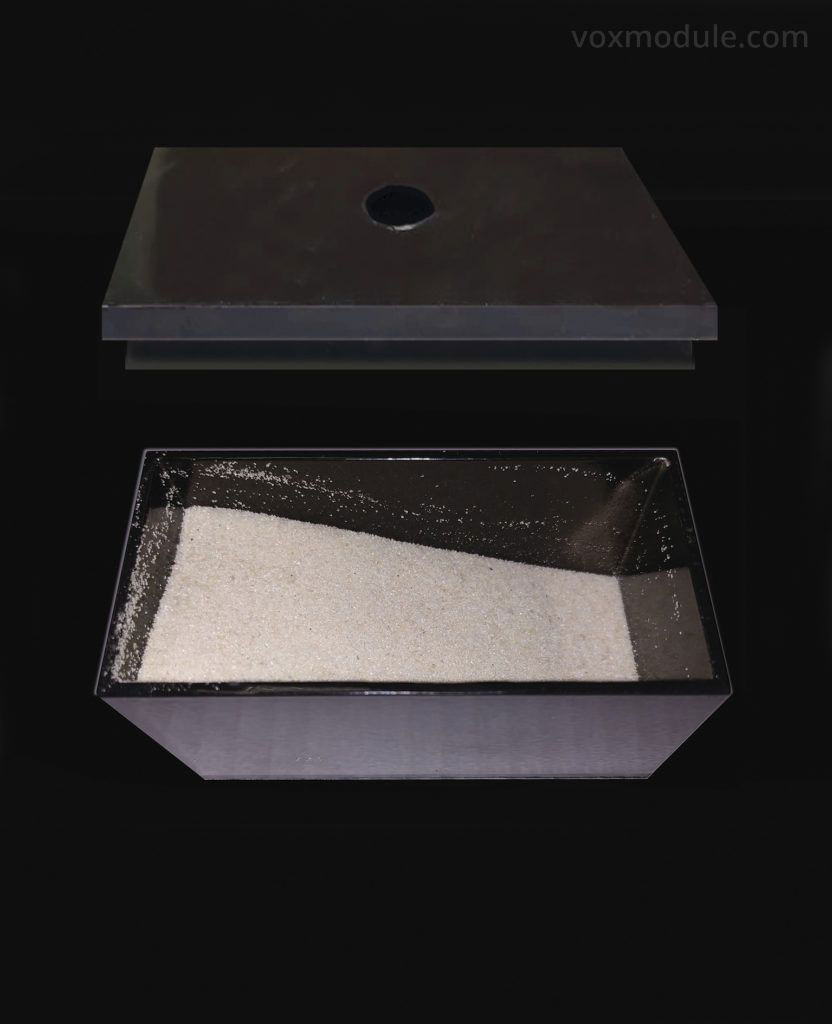

Filling and damping

The support stands are crafted from aluminum alloy and come with spikes made of heat-treated stainless steel. These spikes reduce the contact area and significantly increase the pressure exerted by the elements placed on the shelf, thereby dampening the majority of parasitic vibrations.

The stands are filled with quartz sand, which dampens the chassis and increases the mass of the oscillating system. This lowers its resonant frequency and minimizes the impact of unwanted resonances in the frequency range of sound. We use elastic pads made of special rubber with a low resonance frequency as end caps. All these measures have only one goal: to improve sound quality and its authenticity.